Waterproofing Chemicals

Product Details:

Waterproofing Chemicals Price And Quantity

- 100 Kilograms

Waterproofing Chemicals Trade Information

- 1000 Kilograms Per Day

- 5 Days

Product Description

Waterproofing ChemicalsWe have a carved a prestigious niche in today's highly competitive market as a trusted organization, which is involved in offering Waterproofing Chemicals. In our world-class facilities, these chemicals are formulated with qualitative ingredients and tested on different parameters to ensure their high effectiveness. We offer these chemicals in leakage-free containers to ensure their safe delivery at our clients' end. These Waterproofing Chemicals are widely used for protecting the surfaces of different structures owing to their excellent chemical properties.

Other details:

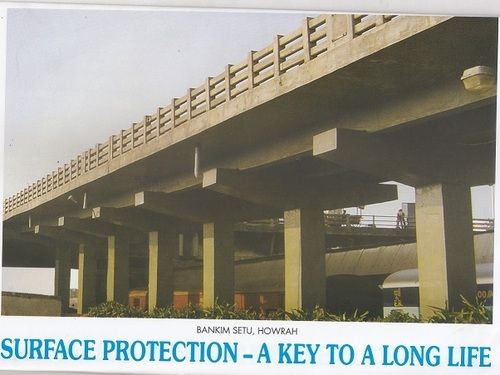

Underside of bridge deck, railing, etc. of bridges and Piers and Substructures which are not in River Bed

Cleaning and drying the surface; applying (@ 0.30 litre per square metre) a coat (DFT of 100-150 micron) of a translucent brown coloured modified phenolic resin based single component high performance polymeric waterproofing compound (sp. gr. 0.87, rosin content nil and a solid content of minimum 0.47%), e.g., PERMAPROOF, with demonstrable properties of resistance to water and acid; applying (@ 0.25 litre per square metre) a top coat of a modified phenolic resin based single component waterproofing compound of grey or other shades (sp. gr. 0.85), e.g., PERMACIL-GA, before the base coat becomes tack-free; permitting the coatings to cure and dry naturally; the 2-coat system shall be impermeable under a waterhead of 20.0 metres.

PERMAPROOF :

Requirement : 0.30 litre/sqm for underside of bridge deck, railing, etc. of bridges and piers and substructures

PERMACIL-GA (or other shades) :

Requirement : 0.25 litre/sqm for underside of bridge deck, railing, etc. of bridges and piers and substructures

Bridge Deck

Cleaning the surface; preparing the surface by acid etching; treating the surface with a two-layer plaster; the first layer shall be 5 mm thick with cement (OPC or slag), admixed with an octadecanoic acid based cementitious waterproofing compound (bulk density not greater than 0.5 gm/cc, moisture content not greater than 2.0% and free fatty acid not greater than 0.2%), e.g., PERMAKAR 3, in the weight ratio of 50:3 for cement and waterproofing compound, further admixed with specially fabricated deformed galvanized steel fibre (@ 150 gm per square metre of treatment surface), e.g., KARFIB; finally providing a 12 mm thick cement-sand (1:2.5) plaster, enriched with polyester fibre, and curing the plastered surface; the treatment shall be impermeable under a waterhead of 20.0 metres.

PERMAKAR 3 :

Requirement : 0.60 kg/sqm for bridge deck

KARFIB :

Requirement : 150 gm/sqm for bridge deck